Comprehensive Insights into Stainless Steel Honeycomb Core: Transforming Modern Metal Fabrication

In the dynamic realm of metal fabrication, the quest for materials that combine strength, durability, lightweight properties, and versatility continuously drives innovation. Among the most revolutionary materials gaining significant prominence is the stainless steel honeycomb core. This exceptional component is transforming industries ranging from aerospace and automotive to architectural design and industrial manufacturing. Goldeco Steel, renowned as a leading metal fabricator, specializes in creating high-quality metal fabricators with expertise in stainless steel honeycomb core fabrication. This article delves deeply into the various facets of this cutting-edge material, shedding light on its design, manufacturing processes, key advantages, and innovative applications. Our aim is to equip you with expert-level knowledge to leverage the potential of the stainless steel honeycomb core in your projects and business strategies.

What is a Stainless Steel Honeycomb Core? An Overview

A stainless steel honeycomb core is a structural material characterized by its intricate honeycomb-shaped pattern composed of stainless steel sheets or plates. This design mimics the natural honeycomb structure found in beehives, optimizing the distribution of forces while minimizing weight. The core essentially functions as an internal reinforcement layer, providing exceptional strength-to-weight ratios and rigidity. It is frequently used as a core material within sandwich panels, where it is sandwiched between facings such as aluminum, steel, or composites to create high-performance, lightweight panels.

The unique properties of stainless steel honeycomb core make it ideal for applications demanding high structural integrity without adding excess weight. Its corrosion resistance, heat resilience, and environmental durability elevate it above other core materials like aluminum or plastic-based honeycombs, especially in harsh conditions.

Engineering and Manufacturing of Stainless Steel Honeycomb Core: Precision and Innovation

The manufacturing process of stainless steel honeycomb core involves meticulous precision and advanced technology. Typically, the process encompasses the following stages:

- Material Selection: High-quality stainless steel alloys such as 304 or 316 are chosen for their corrosion resistance and mechanical properties.

- Sheet Formation: Stainless steel sheets are cut and folded into the characteristic hexagonal cells — the fundamental building blocks of honeycomb structures.

- Corrugation and Expansion: The sheets undergo corrugation, creating a wave-like pattern that enhances strength. These are then expanded to create the full honeycomb pattern.

- Welding and Bonding: The honeycomb sheets are welded along the edges to secure the cellular structure, ensuring uniform cell sizes and stability.

- Cutting and Finishing: Precise cutting to desired dimensions, along with surface finishing processes such as polishing or coating, prepare the core for integration into composite panels.

Cutting-edge machinery such as CNC laser cutters and automated welding systems ensure that each stainless steel honeycomb core produced maintains impeccable quality, tight tolerances, and consistency vital for high-stakes applications.

Key Benefits of Using Stainless Steel Honeycomb Core

Adopting stainless steel honeycomb core offers unparalleled advantages in various engineering and construction projects:

1. Exceptional Strength-to-Weight Ratio

The honeycomb design optimizes structural strength while maintaining a lightweight profile. This is particularly critical in aerospace, automotive, and architectural applications where reducing weight directly impacts performance and fuel efficiency.

2. Superior Corrosion Resistance

Made from stainless steel, this core material exhibits excellent resistance to rust, corrosion, and environmental degradation, ensuring durability in marine, outdoor, and chemically aggressive environments.

3. High Thermal Stability and Fire Resistance

Stainless steel's inherent heat resilience allows honeycomb cores to withstand high temperatures, making them suitable for applications with stringent fire safety standards.

4. Enhanced Structural Integrity

The cellular geometry distributes stresses evenly, reducing the risk of warping or failure under load. The core also adds stiffness to sandwich panels, improving their load-bearing capacity.

5. Versatility in Design and Manufacturing

The method of fabrication enables customization of cell size, wall thickness, and overall panel dimensions, allowing tailored solutions for diverse industry needs.

Industrial Applications of Stainless Steel Honeycomb Core

The unique qualities of the stainless steel honeycomb core make it invaluable across a broad spectrum of industries:

1. Aerospace Industry

In aerospace, weight reduction is paramount. Stainless steel honeycomb cores are used in aircraft panels, flooring, and interior structures, providing the perfect balance of strength, durability, and weight savings.

2. Automotive Manufacturing

High-performance vehicles leverage honeycomb cores in body panels, crash barriers, and soundproofing components, where impact resistance and low weight are essential.

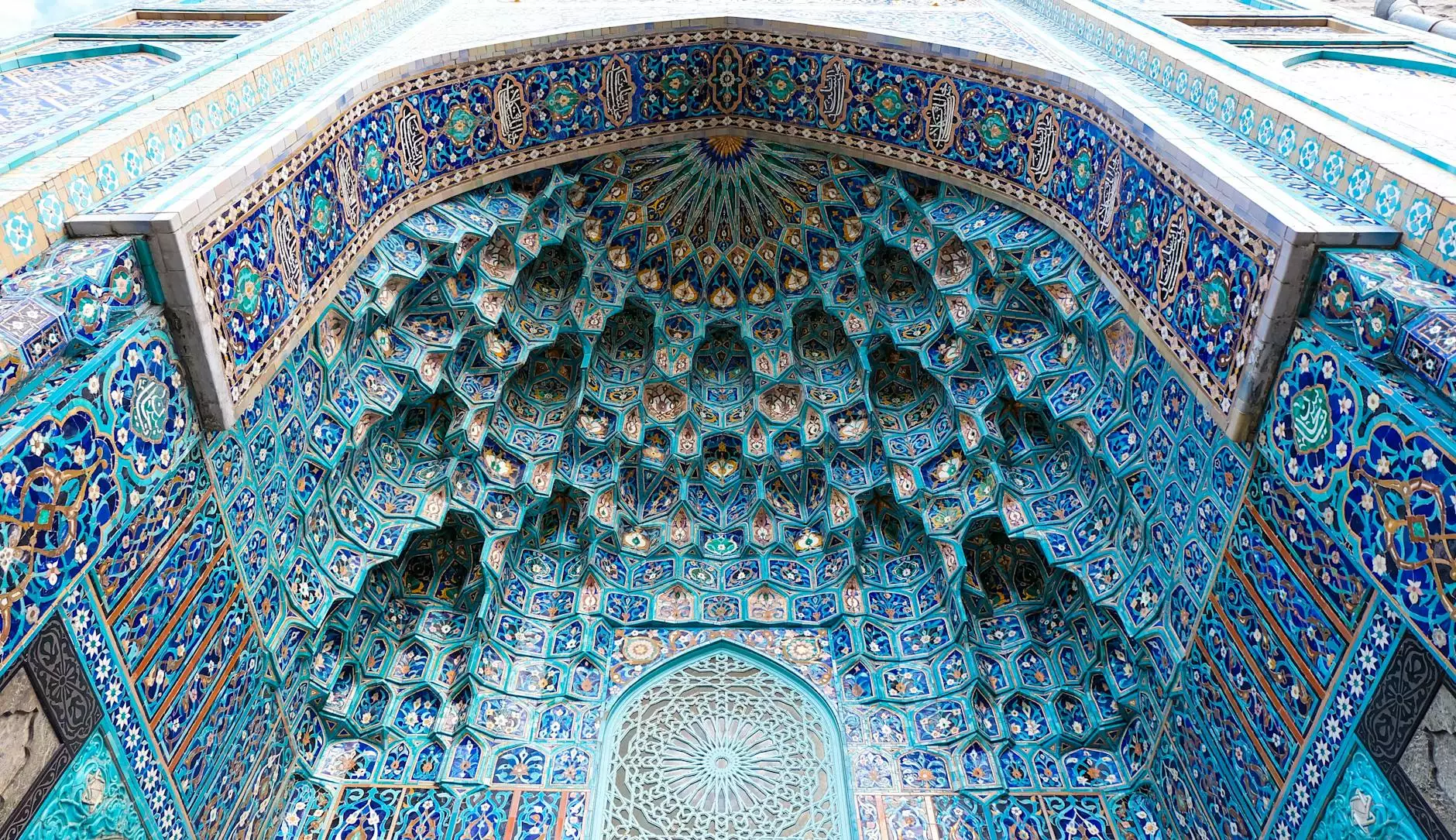

3. Architectural and Building Design

Architectural facades, interior walls, and decorative panels benefit from stainless steel honeycomb cores' aesthetic appeal, corrosion resistance, and structural support.

4. Marine Applications

The marine industry uses these cores extensively in shipbuilding, offshore structures, and luxury yachts to capitalize on their resistance to saltwater corrosion and environmental wear.

5. Industrial Equipment and Appliances

Heavy-duty industrial equipment, cooling systems, and chemical processing machinery incorporate these cores for their strength and temperature resilience.

6. Defense and Military

Defense applications, including armored panels and protective barriers, utilize stainless steel honeycomb cores for their superior impact resistance and durability.

Why Choose Goldeco Steel for Your Stainless Steel Honeycomb Core Needs?

As a specialized metal fabricator, Goldeco Steel offers unmatched expertise in manufacturing custom stainless steel honeycomb cores. Our commitment to quality, precision engineering, and innovation positions us as the ideal partner for projects requiring high-performance core materials. We ensure:

- Customized Solutions: Tailored honeycomb cores to meet specific design and engineering requirements.

- Cutting-Edge Manufacturing: Advanced machinery and processes for consistent quality and tight tolerances.

- Material Expertise: Selection of optimal stainless steel alloys for each application.

- Comprehensive Service: From initial design consultation to final product delivery and installation support.

- Competitive Pricing: Cost-effective solutions without compromising quality or performance.

Partner with Goldeco Steel to harness the full potential of stainless steel honeycomb core technology and elevate your project’s performance, safety, and aesthetic appeal.

Future Trends in Stainless Steel Honeycomb Core Technology

The evolution of metal fabricators is guided by ongoing research into new materials and manufacturing techniques. The future of stainless steel honeycomb cores includes:

- Enhanced Cell Geometry: Development of alternative cell shapes for specific load scenarios.

- Composite Integration: Combining stainless steel honeycombs with composite materials for hybrid solutions.

- Automated Manufacturing: Increased automation for faster turnaround times and tighter quality control.

- Sustainable Production: Adoption of eco-friendly processes and recyclable materials.

- Smart Structural Elements: Embedding sensors within honeycomb cores to monitor structural health in real-time.

Embracing these innovations will further solidify the role of stainless steel honeycomb core in high-end engineering and design solutions, fostering safer, lighter, and more durable structures worldwide.

Conclusion: Elevate Your Projects with the Power of Stainless Steel Honeycomb Core

The stainless steel honeycomb core stands as a testament to modern innovation in metal fabrication. Its remarkable strength, lightweight profile, superior corrosion resistance, and versatility enable the creation of advanced structures across industries. As a dedicated metal fabricator, Goldeco Steel is committed to delivering high-quality, custom solutions that meet the evolving demands of clients worldwide. Whether enhancing aerospace components, architectural facades, or industrial equipment, the integration of stainless steel honeycomb cores can significantly elevate project performance and longevity.

Invest in the future of structural engineering with our expert services. Discover how Goldeco Steel’s mastery in fabricating metal fabricators and core materials like stainless steel honeycomb core can turn your design visions into reality with unmatched precision and quality.